VortexWell – Solving Resonance Failure Issues

At Okazaki, we’ve always made it our absolute focus to solve issues that we know our clients constantly face. So, when it comes to solving thermowell resonance failure issues, we’ve always strived to use the latest technological advances to find the latest solutions. Which is why since the introduction of the VortexWell thermowell in 1999, our engineers have meticulously developed our solution; ensuring you benefit from market-leading temperature measurement.

A simple and effective solution, we recognise that the industry has been facing several issues when it comes to vortex induced resonance failures. This is why we’ve continued our extensive research and development to find the most cost-effective and vastly technically advanced product available to you. We also know that you want to find a solution that easily assesses and calculates potential issues. The VortexWell meets all of these requirements and more.

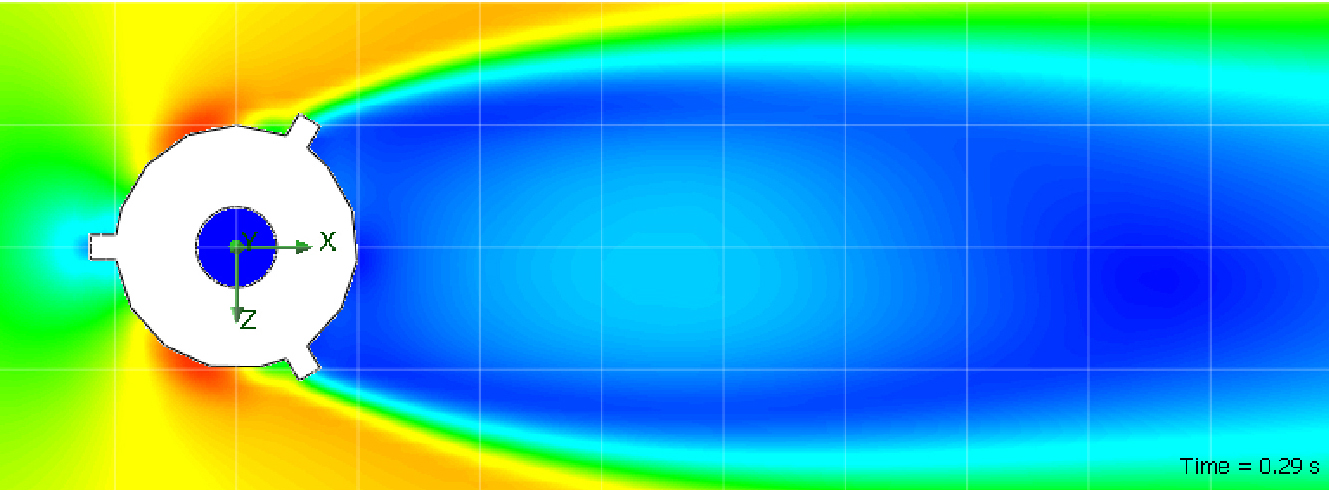

Through its clever helical strake design, the VortexWell is able to encounter the issues faced by fluid flowing around a blunt object in its path; forming vortices downstream of the object – also known as vortex shedding. We’re fully aware of the implications from the vortex shedding frequency or Stroudhal frequency approaching the thermowell natural frequency. When faced with this situation, the tip displacement and stresses become greatly magnified; causing the thermowell to fail. We also know that even when the thermowell has passed the ASME PTC 19.3 TW-2010 regulation, failures can still happen.

In considering alternative solutions to solve the original cause of the problem of vortex induced vibration rather than just masking the symptoms, our engineers looked at several ideas including adding a vortex suppression device, avoiding resonance, increasing damping and using a streamlined cross section.

Eventually our engineers discovered that incorporating a helical strake as a vortex suppression method certainly delivers the best performing and safest thermowell solution available. Through this technique, engineers found that not only the flow disturbance was minimised thanks to its aerodynamic tip, but it also ended the possibility of vortex induced vibration.

If you’re interested in finding out how Okazaki can help you deal with your temperature challenges, contact us on sales@okazaki-mfg.co.uk.

Image 1: Showing flow around a standard Thermowell

Image 2: Showing flow around our VortexWell Thermowell